Have you ever wondered about the journey of your favorite pair of shoes from design to the moment they touch your feet? Shoes are more than just fashion statements; they are products of intricate craftsmanship and innovative technology. In this article, we will dive deep into the fascinating process of shoe manufacturing. Whether you’re a shoe enthusiast, a fashion lover, or a business owner in the footwear industry looking to enhance your understanding, this guide is for you!

The Journey of Shoe Production

The process of making shoes is a blend of art and science. It typically involves several stages, including design, material selection, cutting, stitching, and finishing. Let’s explore each step of this fascinating journey.

Step 1: Design and Conceptualization

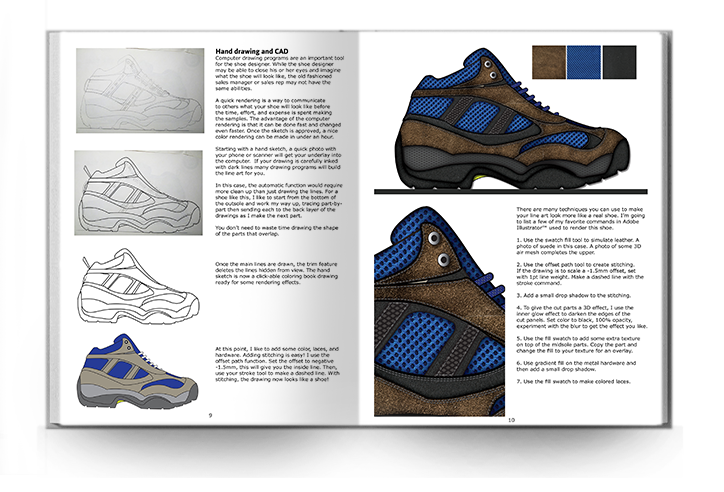

Every shoe begins with an idea. Designers sketch their concepts using computer-aided design (CAD) software, allowing them to visualize the shoe’s form, function, and aesthetics. During this phase, considerations such as target market, materials, and purpose are crucial. Designers not only focus on the appearance but also on comfort and practicality. For instance, the collaboration between Adidas and Beyoncé for the Ivy Park line illustrates how design meets functionality while appealing to fashion lovers.

Real-World Example: Nike’s Sustainable Design

Nike has made significant strides in sustainable design. Their ‘Move to Zero’ initiative aims at zero carbon and zero waste, showcasing how innovative design can lead to environmentally friendly footwear solutions. Learn more about their sustainable practices here.

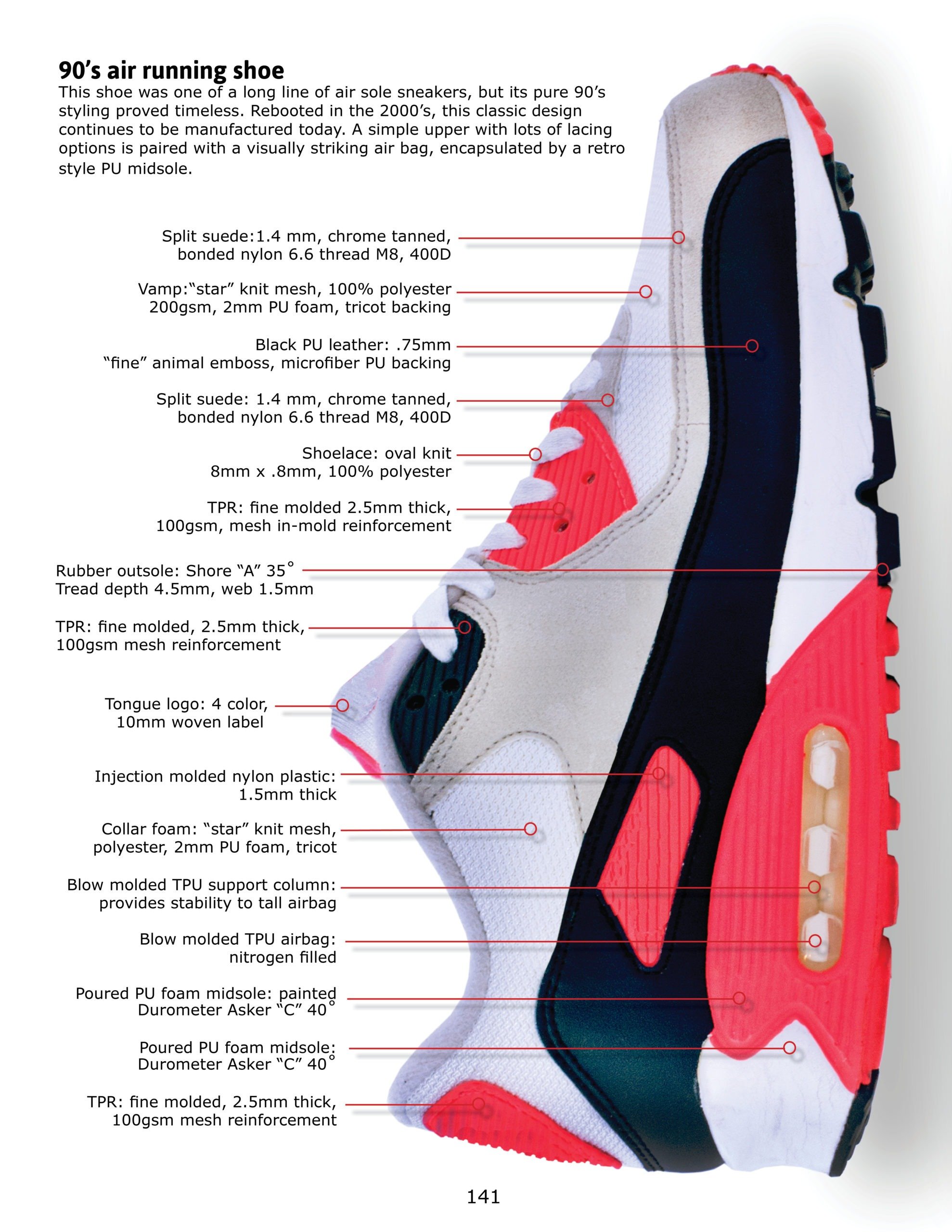

Step 2: Material Selection

Once the design is finalized, the next step is choosing the right materials. Common shoe materials include leather, synthetic fabrics, rubber, and foam. Each material has its unique advantages and drawbacks. For instance, leather offers durability and breathability, while synthetic materials can be more affordable and easier to maintain. Understanding the characteristics of different materials helps brands cater to consumer preferences.

Comparison Table: Common Shoe Materials

| Material | Pros | Cons |

|---|---|---|

| Leather | Durable, breathable, molds to the foot | Expensive, requires maintenance |

| Synthetic Fabrics | Cost-effective, water-resistant | Less breathable, may wear out faster |

| Rubber | Slip-resistant, flexible | Can be heavy, not breathable |

| Foam | Lightweight, cushioning | Can deteriorate quickly, less durable |

Step 3: Cutting the Materials

The cutting process involves utilizing specialized machines to precisely cut out the shapes of various shoe components like the upper, lining, and sole. This step is crucial as inaccuracies can lead to waste and misaligned designs. Some brands employ laser cutting technology for enhanced precision and efficiency, resulting in better fits and reduced production time.

Case Study: Adidas’ Laser Cutting Technology

Adidas has embraced laser cutting technology in their production process to enhance precision and minimize material waste. This innovative approach not only boosts efficiency but also aligns with their sustainability goals. You can read more about their cutting-edge techniques in this report.

Step 4: Assembly and Stitching

After the materials are cut, they are assembled and stitched together. Skilled workers meticulously join the pieces, ensuring the integrity and durability of the shoe. Advanced brands often use a combination of traditional craftsmanship and automated processes to maintain high quality while keeping up with demand.

Highlight: The Art of Hand-Stitching

Hand-stitching adds a personal touch to high-end footwear. Brands like John Lobb and Ferragamo emphasize this method, showcasing the marriage of craftsmanship and luxury. While it requires more time, the result is a shoe that stands out in quality and uniqueness.

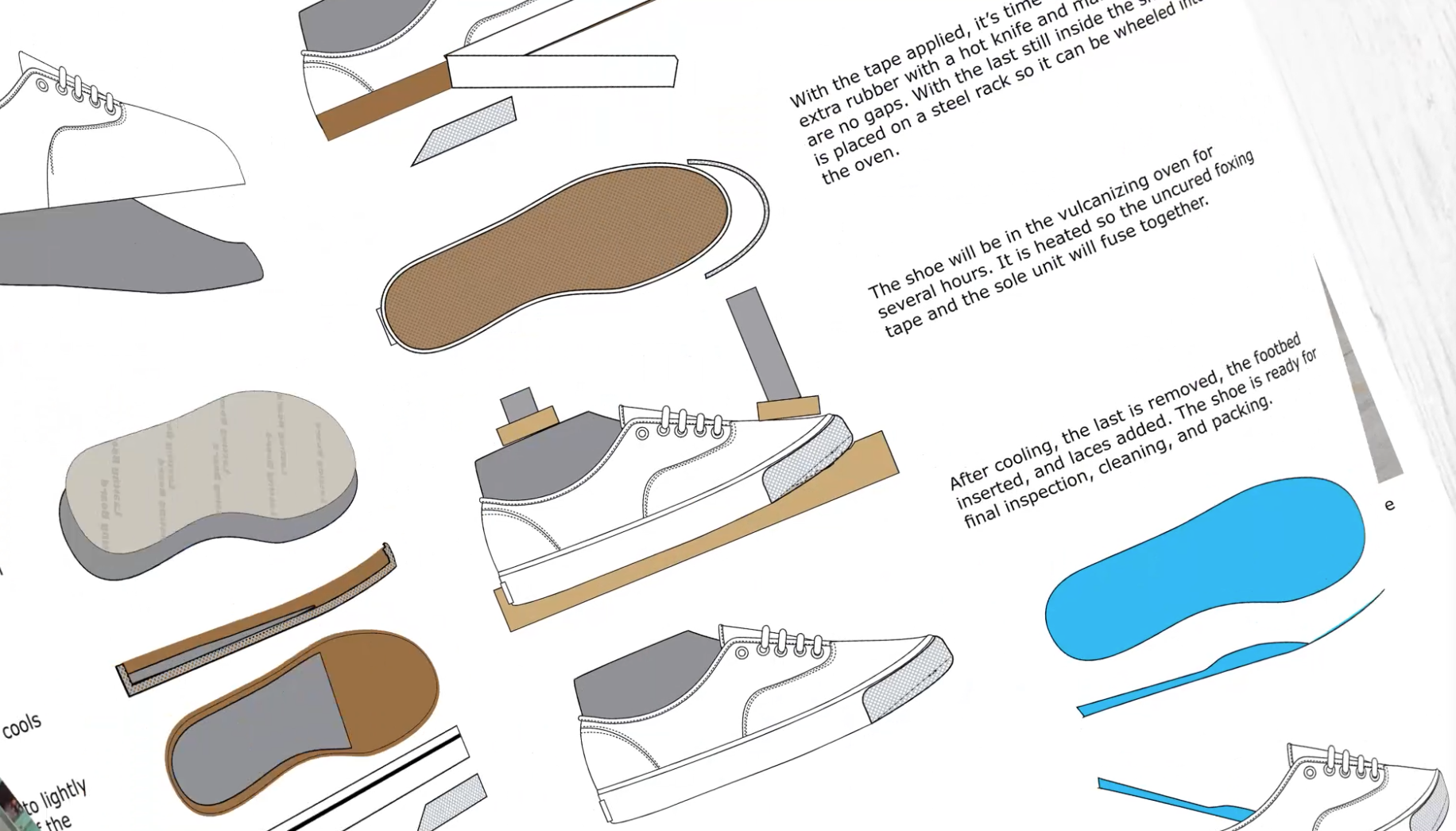

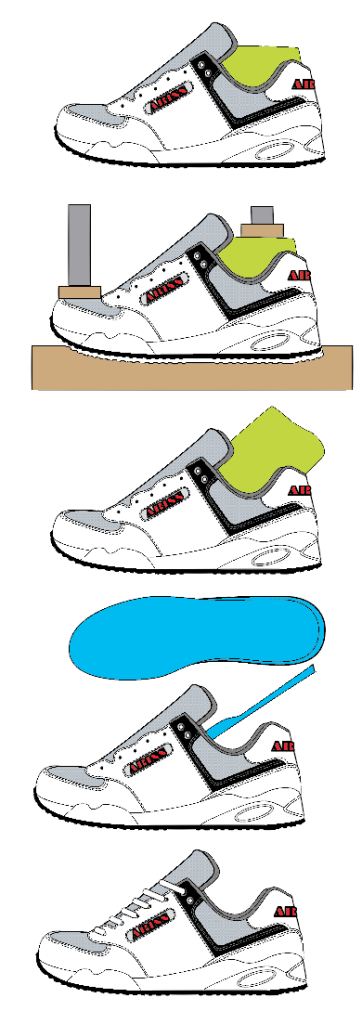

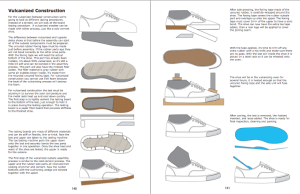

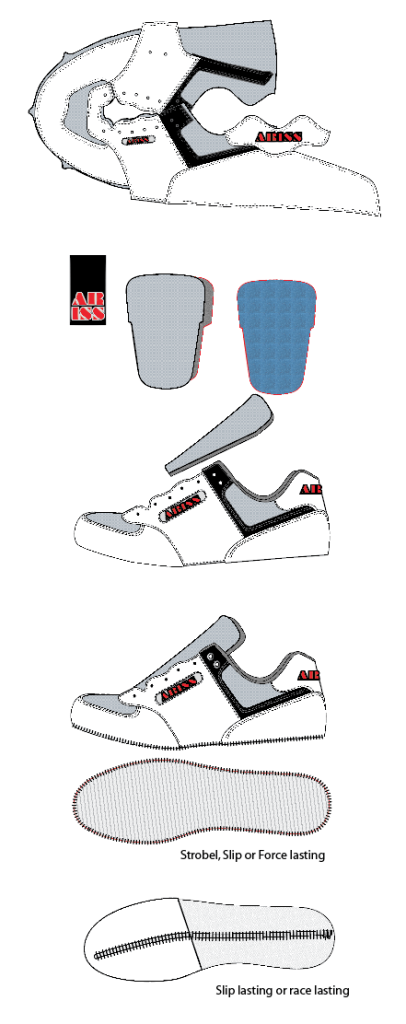

Step 5: Lasting the Shoe

The lasting process involves shaping the shoe around a mold or ‘last’ that replicates the contours of a foot. This step is essential for comfort, fit, and style. Lasting can be done in various ways: slip-lasted for a softer feel or Goodyear welted for durability. Brands choose the technique based on their desired shoe characteristics.

Pros and Cons of Lasting Techniques

- Slip Lasting: Pros: Lightweight, flexible. Cons: Less durable.

- Goodyear Welting: Pros: Long-lasting, can be resoled. Cons: Heavier, takes longer to make.

Step 6: Finishing Touches

After assembling and lasting, the shoe needs finishing touches. This includes polishing, adding laces, and quality checks to ensure everything meets the brand’s standards. These final steps can significantly impact a shoe’s overall look and customer satisfaction.

Coloring and Branding

The coloring process adds character to shoes. Brands often use dyes or paints to achieve the desired color palette, while branding elements like logos are intricately added to enhance recognition. The collaboration between PUMA and Rihanna for the Fenty line is a great example of how branding can be creatively integrated into the design.

Exploring Different Types of Footwear

Shoes come in a plethora of styles, each designed for various purposes and preferences. Here’s a closer look at some popular types of footwear.

Casual Shoes

Casual shoes are designed for comfort and everyday wear. Sneakers, loafers, and canvas shoes fall into this category. Brands like Vans and Converse have made their mark by providing stylish yet comfortable options for casual wear.

Formal Shoes

Formal shoes are essential for professional settings and special occasions. Oxfords, brogues, and dress boots are popular choices. Craftsmanship plays a pivotal role, with brands like Allen Edmonds showcasing their dedication to quality through traditional manufacturing techniques.

Sports Footwear

Sports shoes are engineered for specific athletic activities. Running shoes, basketball shoes, and cross-trainers are designed to provide support, cushioning, and traction. Brands like New Balance and Asics focus on performance, utilizing cutting-edge technology to enhance athletic experiences.

Consumer Considerations: What to Look For in Shoes

When shopping for shoes, you must consider various factors to ensure you purchase a product that meets your needs. Here’s what to keep in mind:

Comfort

Comfort should always be a priority. Look for shoes with adequate cushioning, arch support, and a proper fit. Brands like Skechers are known for their comfort-focused designs, offering a range of styles that prioritize foot health.

Durability

Investing in durable footwear can save you money in the long run. Look for quality materials and construction. For example, shoes made with full-grain leather and reinforced stitching tend to last longer than their synthetic counterparts.

Style and Versatility

Your shoes should reflect your personal style. Versatile designs that can transition from casual to formal settings are ideal. Brands like Clarks and Dr. Martens offer stylish options suitable for various occasions.

Frequently Asked Questions (FAQs)

1. How long does it take to make a pair of shoes?

The time to produce a pair of shoes varies by brand and manufacturing methods. Simple designs may take a few hours, while handcrafted luxury shoes can take weeks or even months.

2. What shoe materials are the most sustainable?

Materials like organic cotton, cork, and recycled plastics are considered sustainable options. Brands increasingly opt for eco-friendly materials to minimize environmental impact.

3. How can I tell if my shoes are made well?

Check for even stitching, high-quality materials, and a sturdy construction. Quality brands often highlight their craftsmanship details on labels.

4. What’s the best way to care for my shoes?

Regular cleaning, conditioning leather, and proper storage can prolong your shoes’ lifespan. Each material has specific care requirements, so refer to brand guidelines for the best practices.

5. Are expensive shoes worth the investment?

While not all expensive shoes guarantee quality, many high-end brands invest in craftsmanship and materials that result in better comfort and durability, making them worth the investment for serious shoe lovers.

6. What are the signs of a good running shoe?

Look for good cushioning, a proper fit, and support features specific to your running style. Consult with specialists at running stores for personalized recommendations.

7. How do I choose the right size?

Always measure your feet with both length and width. Fit can vary by brand, so refer to their sizing guides to find the perfect match.

8. What are sustainable shoe brands I can trust?

Brands like Veja, Allbirds, and Rothy’s focus on sustainability and ethical production. Researching a brand’s practices can help you make informed choices.

9. Can shoes be repaired?

Many shoes can be repaired, particularly high-quality ones. Soles can be replaced, and stitching can be repaired, giving your favorite pair a longer life.

10. How are athletic shoes different from casual shoes?

Athletic shoes are specifically designed for sports activities, focusing on support and performance. Casual shoes prioritize comfort and style for everyday wear.

The Future of Shoe Manufacturing

The footwear industry is evolving rapidly with technology playing a significant role. Innovations in 3D printing, sustainable materials, and automation are set to revolutionize how shoes are made. Companies are exploring ways to reduce waste and enhance customization, allowing consumers to personalize their footwear experience.

The Role of Technology in Footwear

3D printing allows brands to create shoes tailored to individual foot shapes, promoting better fit and function. This shift signifies a move towards more personalized footwear solutions and reduces the need for mass production, aligning with sustainability goals.

Conclusion

Understanding how shoes are made not only enriches our appreciation for footwear, but it also empowers consumers to make informed choices. From design to production, the journey of shoes is filled with artistry and innovation. Whether you’re a shoe lover or an entrepreneur in the industry, knowing these processes can provide insight into the factors that impact shoe quality, style, and sustainability.