Welcome to the intriguing world of shoe-making! If you are passionate about footwear, whether as a fashion lover, a shoe enthusiast, a professional craftsman, or a business owner, this article is your go-to guide on how to make shoes. Here, we will explore the journey from concept to finished product, incorporating real-world footwear experiences, insights, and tips. Let’s step into the process!

Understanding the Shoe-Making Process

Making shoes is an art form that blends creativity with engineering. The journey typically involves several stages, from design to production. Below, we’ll delve into each phase to give you a clear understanding of how shoes are made.

1. Design and Planning

Before a shoe is made, it all starts with the design. This is where creativity meets practicality.

Sketching Your Idea

Designing a shoe often begins with sketches. This stage involves brainstorming ideas that cater to style, functionality, and target audience needs. Fashion designers often use computer-aided design (CAD) software to refine their concepts. Popular tools include Adobe Illustrator and specialized applications like Clo3D.

Case Study: The Journey of Nike Air Max

The Nike Air Max was born from a simple design idea in the 1970s, evolving through customer feedback and technological advancements. The collaboration between designers and engineers led to the first visible air cushioning in the sole, revolutionizing comfort and style. This case demonstrates the importance of design and innovation in shoe-making.

2. Material Selection

Materials play a crucial role in determining the quality and look of the shoes.

Types of Materials

Common materials used in shoe-making include leather, synthetic fabrics, rubber, and foam. Each material has its pros and cons.

| Material | Pros | Cons |

|---|---|---|

| Leather | Durability, breathability, luxury look | Expensive, requires care |

| Synthetic Fabrics | Cost-effective, lightweight, versatile | Less breathable, may not last long |

| Rubber | Waterproof, good traction | Less stylish, can be heavy |

| Foam | Comfort, lightweight | Less durable, may compress over time |

3. Creating a Prototype

The next step is to create a prototype of the shoe. This involves a “mock-up” to assess the design and functionality.

Using 3D Printing Technology

Many modern designers utilize 3D printing to produce prototypes. This technology allows for rapid iteration and testing of designs. It provides an affordable way to evaluate how different materials and styles come together.

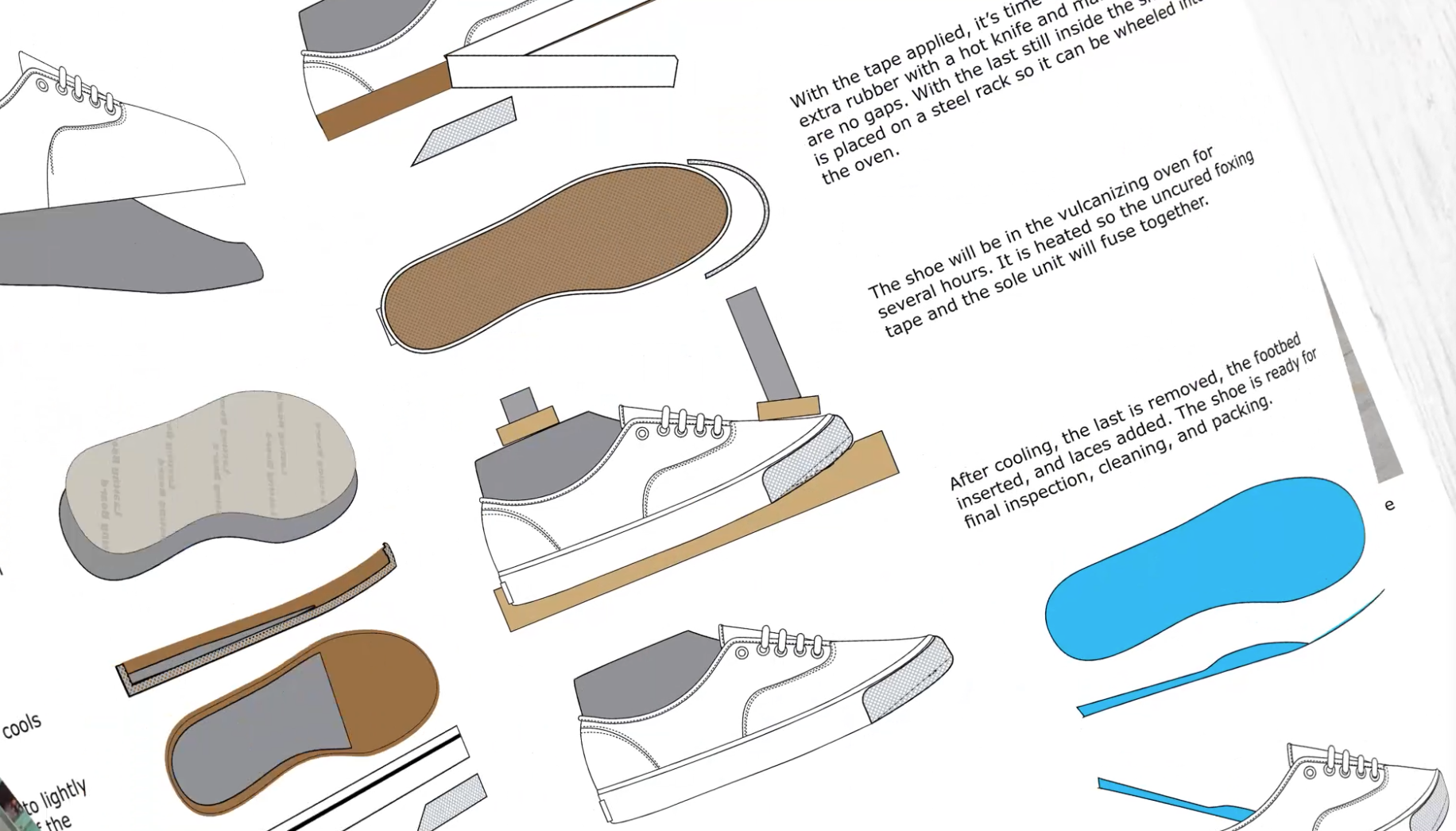

4. Production

Once the prototype is approved, it’s time for production. This stage can vary significantly depending on the methods used and the scale of production.

Handmade vs. Mass Production

Handmade shoes often involve craftsmanship, where each piece is assembled with precision. Brands like Allen Edmonds and John Lobb are famous for their handmade shoes. In contrast, mass production emphasizes efficiency and speed, as seen with companies like Adidas and Puma.

5. Quality Control

Quality assurance is crucial in shoe-making. Each pair must be inspected for defects and performance. Brands often implement rigorous testing processes, including wear tests and physical inspections.

Popular Footwear Trends and Innovations

The footwear industry is continually evolving with new trends and technologies. Let’s explore some of the current popular trends and innovations.

Sustainable Footwear

Eco-friendly materials and manufacturing processes are becoming increasingly important to consumers. Brands like Allbirds and Veja prioritize sustainability by using recycled materials and reducing carbon footprints.

Smart Shoes

With the rise of wearable technology, smart shoes equipped with sensors and connectivity are becoming more common. These shoes can monitor your activity levels, gait, and even help with navigation. Examples include the Nike Adapt and Under Armour HOVR series.

Tips for Aspiring Shoemakers

If you’re interested in making your own shoes, consider these tips:

1. Start Small

Begin by creating simple designs to hone your skills. Use readily available materials to practice techniques like stitching and assembling.

2. Take Courses

Many online resources and local classes offer courses in shoe-making. Platforms like Skillshare and Udemy feature courses led by experienced shoemakers.

3. Join a Community

Engage with other shoemakers or enthusiasts through social media groups or local meetups. Sharing experiences can provide valuable insights and encouragement.

FAQs about Shoe Making

1. What tools do I need to make shoes?

Basic tools include a cutting mat, scissors, awl, needle, thread, and glue. Specialty tools may include a shoe last and a stitching machine.

2. Can I make shoes at home?

Absolutely! Many people create shoes as a hobby at home. Start with simple patterns and materials to build your skills.

3. How long does it take to make a pair of shoes?

The timeframe can vary significantly. Handmade shoes typically take several hours to days, while mass production can see thousands of pairs made in a single day.

4. Is it expensive to start making shoes?

The initial investment can vary based on tools and materials. It’s possible to start with a minimal budget by using basic tools and repurposed materials.

5. What are the most common types of shoes made by artisans?

Artisans often focus on dress shoes, boots, sandals, and custom sneakers. Each type requires different skills and techniques.

6. How do I design shoes for specific markets?

Research your target market’s preferences, trends, and pain points. Consider conducting surveys or focus groups to gather insights from potential customers.

7. What are some common mistakes in shoe-making?

Common errors include poor material selection, improper fitting, and lack of attention to detail. It’s essential to take your time and learn from each attempt.

8. Can I sell the shoes I make?

Yes! Once you have honed your skills, you can sell your designs online or at local craft fairs. Establishing a brand can create more opportunities.

9. Is it necessary to learn from a professional?

While not mandatory, learning from professionals can fast-track your skills and knowledge. Consider mentorship programs or apprenticeship opportunities.

10. What’s the future of shoe-making?

As technology advances, we can expect more innovations in materials, design processes, and sustainability practices. 3D printing and customization will likely play significant roles.

11. How can I protect my designs legally?

Consider registering your designs with the U.S. Patent and Trademark Office (USPTO) to protect your intellectual property.

Conclusion

Creating your own shoes can be an incredibly rewarding journey. By understanding the shoe-making process, keeping an eye on trends, and engaging with the community, you can turn your passion into a fulfilling hobby or even a business. Whether you choose to make handmade shoes or delve into mass production, there’s always something new to learn in the world of footwear. Now lace up your creativity and start your shoe-making adventure!