Introduction: The Evolution of Footwear Production

The footwear industry has long been synonymous with creativity, craftsmanship, and style. However, the traditional methods of producing shoes often come with hefty price tags that reflect labor-intensive processes and raw material costs. In recent years, a surge of technological innovations has emerged, aimed at reducing the costs of shoe production without sacrificing quality. These advancements not only promise to enhance the efficiency of footwear manufacturing but also open the door to sustainable practices that benefit both the environment and the consumer. This article explores how new technologies are transforming the footwear landscape, providing real-world examples, case studies, and a breakdown of the benefits and drawbacks of these innovative solutions.

The Role of Technology in Footwear Production

As demand for affordable yet stylish footwear continues to rise, the industry is increasingly turning toward technology to streamline production processes and reduce costs. Various technologies, such as 3D printing, automated cutting systems, and smart materials, are redefining traditional manufacturing. These innovations are becoming essential tools for brands looking to remain competitive while adhering to consumer expectations for both quality and affordability.

Understanding 3D Printing in Footwear Manufacturing

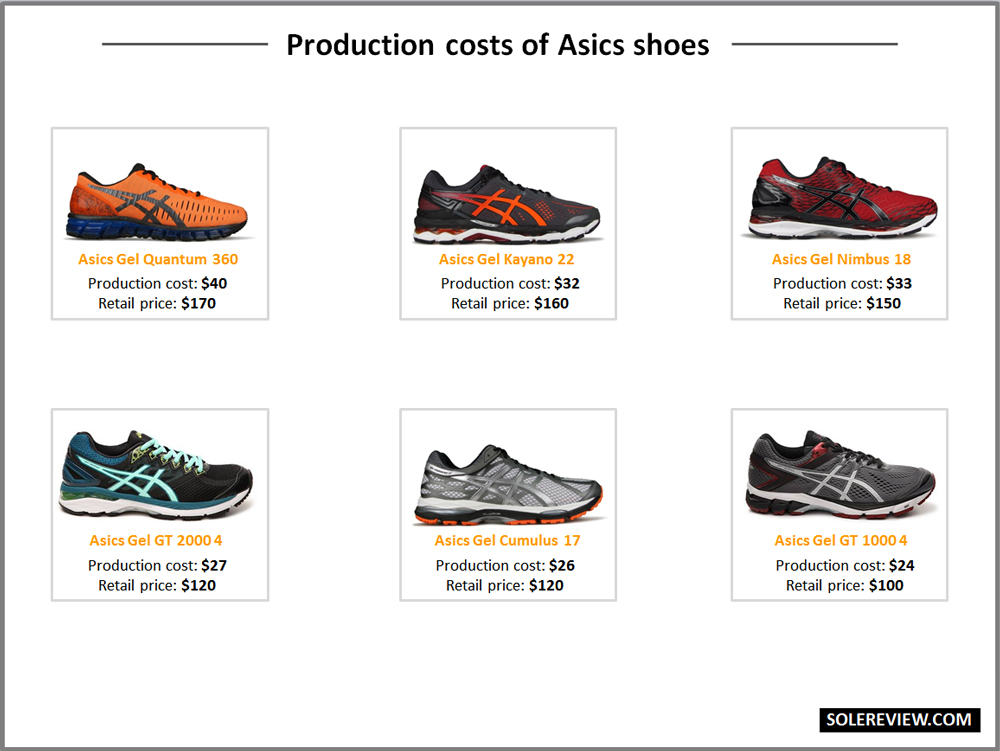

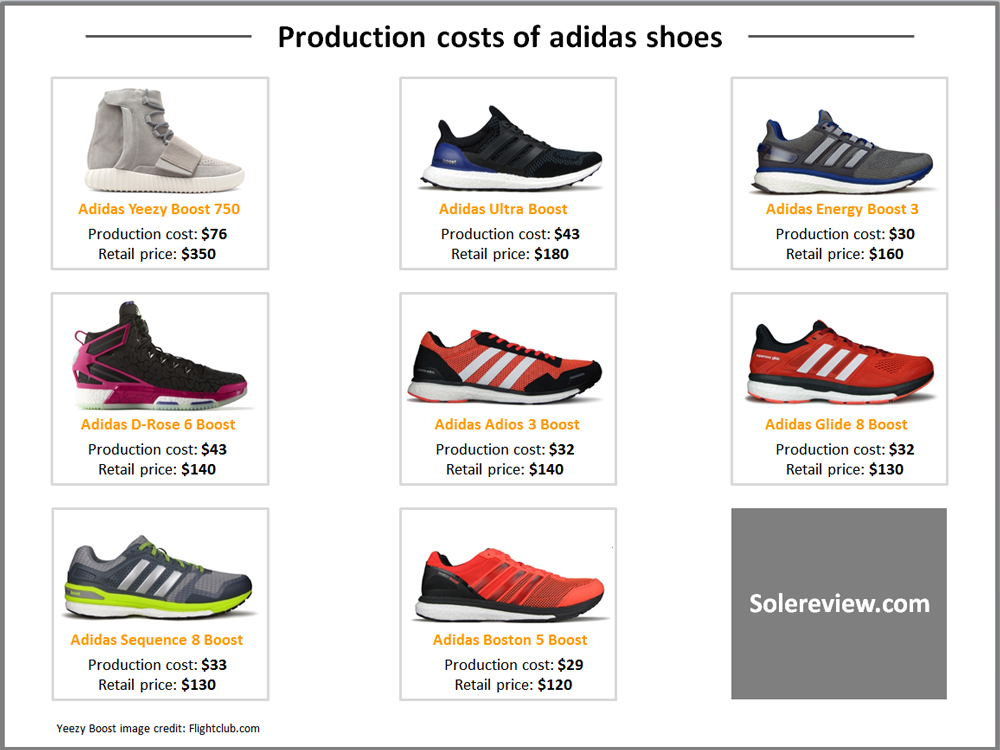

3D printing has emerged as a game-changer in the footwear industry. By allowing manufacturers to create prototypes quickly and cost-effectively, this technology reduces the time and resources needed for shoe production. Brands can now produce customized designs that meet the specific needs of consumers, all while keeping costs low. Adidas is a prime example, having introduced its Futurecraft 4D sneaker, which utilizes digital light synthesis technology to produce the midsole in a matter of hours. The ability to print shoes on demand not only eliminates excess inventory costs but also leads to more sustainable practices by reducing waste.

Case Study: Adidas’ Futurecraft 4D

Adidas’s Futurecraft 4D series showcases the potential of 3D printing in footwear. Initially launched in limited quantities, the sneaker features a highly complex lattice structure, designed for comfort and performance. The 4D printing process minimizes material waste significantly as it utilizes only the necessary materials to create the shoe. With each sneaker taking less than an hour to produce, Adidas has been able to lower production costs while increasing design flexibility.

Automated Cutting Systems: Reducing Labor Costs

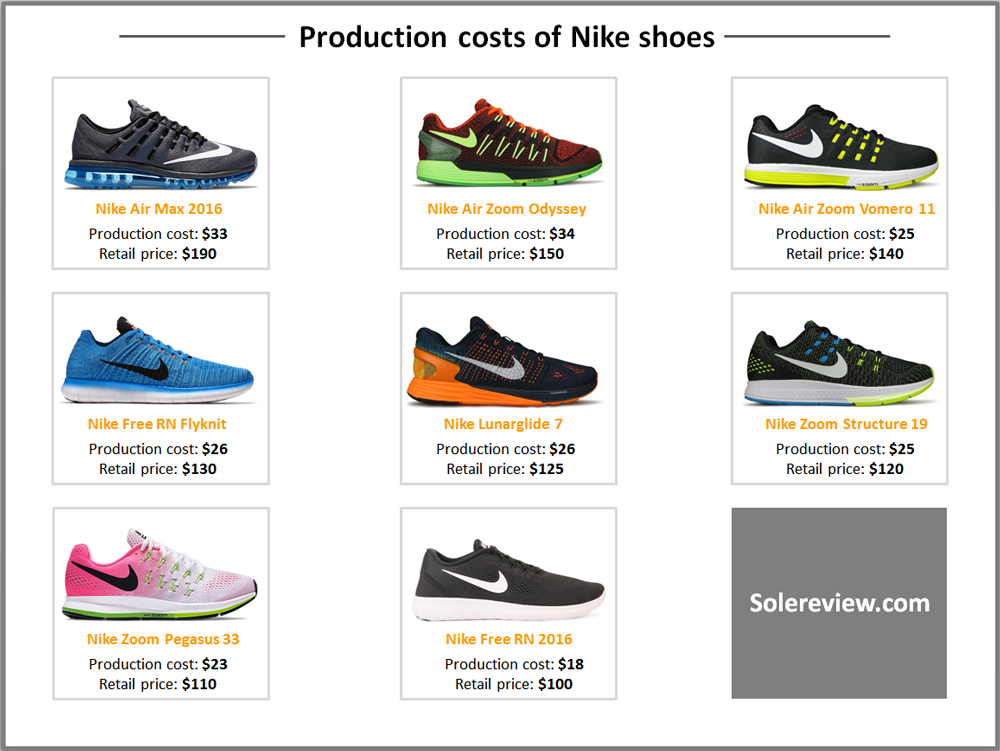

Another notable technology in shoe production is automated cutting systems. These advanced machines use computer-controlled blades to cut materials with precision, drastically reducing labor costs associated with manual cutting. By incorporating automation, brands can produce shoes faster and more accurately, ensuring consistency in quality. For instance, brands like Nike have implemented laser cutting technologies that enhance efficiency and allow for more intricate designs without the added production time.

Real-World Experience: Nike’s Laser Cutting Technology

Nike has been at the forefront of integrating advanced technologies in its production processes. The company’s use of laser cutting has not only streamlined the manufacturing process but also reduced material waste by optimizing fabric usage. This technology has enabled Nike to produce shoes more sustainably while also maintaining high-quality standards. The result? A reduced production cost combined with an impressive product range that caters to diverse consumer needs.

Pros and Cons of New Technologies in Shoe Production

While the integration of new technologies in shoe production offers numerous advantages, it’s essential to understand the potential drawbacks as well. Below is a comprehensive comparison of the pros and cons of these technological advancements.

| Pros | Cons |

|---|---|

| 1. Cost Reduction: Significant decrease in production costs through automation and efficient materials usage. | 1. Initial Investment: High upfront costs associated with acquiring advanced technology. |

| 2. Sustainability: Reduction in waste and resource consumption aligns with eco-friendly practices. | 2. Technology Dependence: Over-reliance on technology can lead to vulnerabilities in production. |

| 3. Customization: Enhanced ability to create customized shoes that meet consumer preferences. | 3. Quality Control: New manufacturing processes may introduce inconsistencies if not monitored properly. |

| 4. Speed: Faster production times lead to quicker market delivery. | 4. Skill Gap: Workers may need to be trained in new technologies, which can lead to temporary disruptions. |

Tips for Adopting New Technologies in the Footwear Industry

For footwear brands looking to integrate new technologies into their production processes, here are some actionable tips that can streamline the transition:

- Assess Industry Needs: Conduct thorough research to determine which technologies best address your specific production challenges.

- Invest in Training: Ensure that your team is equipped to handle new technologies by providing training and resources.

- Start Small: Pilot new technology on a small scale before fully integrating it into your production line.

- Monitor Performance: Collect and analyze data to evaluate the effectiveness of the new technology and adjust as needed.

- Collaborate with Experts: Partner with technology providers to understand the best practices and optimize your production processes.

Featured Product: Nike Air Zoom Alphafly NEXT%

The Nike Air Zoom Alphafly NEXT% exemplifies how cutting-edge technology can elevate performance footwear. This shoe incorporates a carbon-fiber plate and a ZoomX foam sole, leading to unparalleled energy return and speed for runners. The innovative design reduces the time spent in production while maximizing the shoe’s performance capabilities. Adopting technologies like these can significantly improve the image and sales prospects of a footwear brand.

FAQs: Understanding the New Technologies in Footwear Production

1. What is the primary benefit of 3D printing in shoe production?

3D printing allows brands to rapidly prototype designs, reduce production time, and create customized solutions that cater to consumer needs. This results in lower costs and minimal waste.

2. How does automated cutting technology improve shoe production?

Automated cutting technology enhances efficiency by reducing manual labor, ensuring precise cuts, and optimizing material usage, which significantly lowers production costs.

3. Are there environmental benefits to using new manufacturing technologies?

Yes, many new technologies reduce material waste and energy consumption, leading to more sustainable production practices. This is vital for brands looking to enhance their eco-friendly credentials.

4. What challenges might brands face when implementing new technologies?

Brands may encounter high initial investment costs, a skills gap among workers, and potential disruptions during the transition phase. However, with proper planning and training, these challenges can be managed.

5. How can brands ensure quality control with new technologies?

Implementing strict monitoring processes and using data analytics to track performance can help maintain quality control, even as new technologies are integrated into production.

6. Can smaller brands afford these new production technologies?

While initial investment costs can be high, smaller brands can start by piloting technologies on a smaller scale and seek financing options to spread out expenses.

7. What is the role of consumer feedback in adopting new technologies?

Consumer feedback is invaluable as it can guide brands in understanding market demand and tailoring their products to meet consumer expectations using innovative technologies.

8. How does quick prototyping impact the design process?

Quick prototyping allows designers to iterate and refine their ideas rapidly, leading to more innovative and consumer-centric products while reducing time to market.

9. What future trends can we expect in footwear production technologies?

We can anticipate further advancements in AI-driven design processes, increased automation, and even more sustainable materials as brands strive to meet consumer demands for quality and low environmental impact.

10. Is there evidence of increased sales due to technology adoption?

Brands implementing new technologies have reported increased sales due to the ability to create unique, high-quality products that resonate with consumers, leading to enhanced brand loyalty.

11. How can brands position themselves competitively in a tech-driven footwear market?

By investing in innovative technologies, focusing on sustainability, and maintaining strong communication with consumers, brands can differentiate themselves and capture market share in a rapidly evolving industry.

Conclusion: Embracing Change in the Footwear Industry

The advancements in technology are not merely trends; they represent a fundamental shift in how footwear is produced. By embracing innovations such as 3D printing and automated cutting, brands can significantly reduce production costs while enhancing quality and sustainability. As the competition intensifies and consumer expectations evolve, the footwear industry must adapt and innovate. The future looks bright for those willing to embrace change, making it an exciting time for both brands and consumers alike.